gallery

Here are photos of the progress of my projects I'm working on

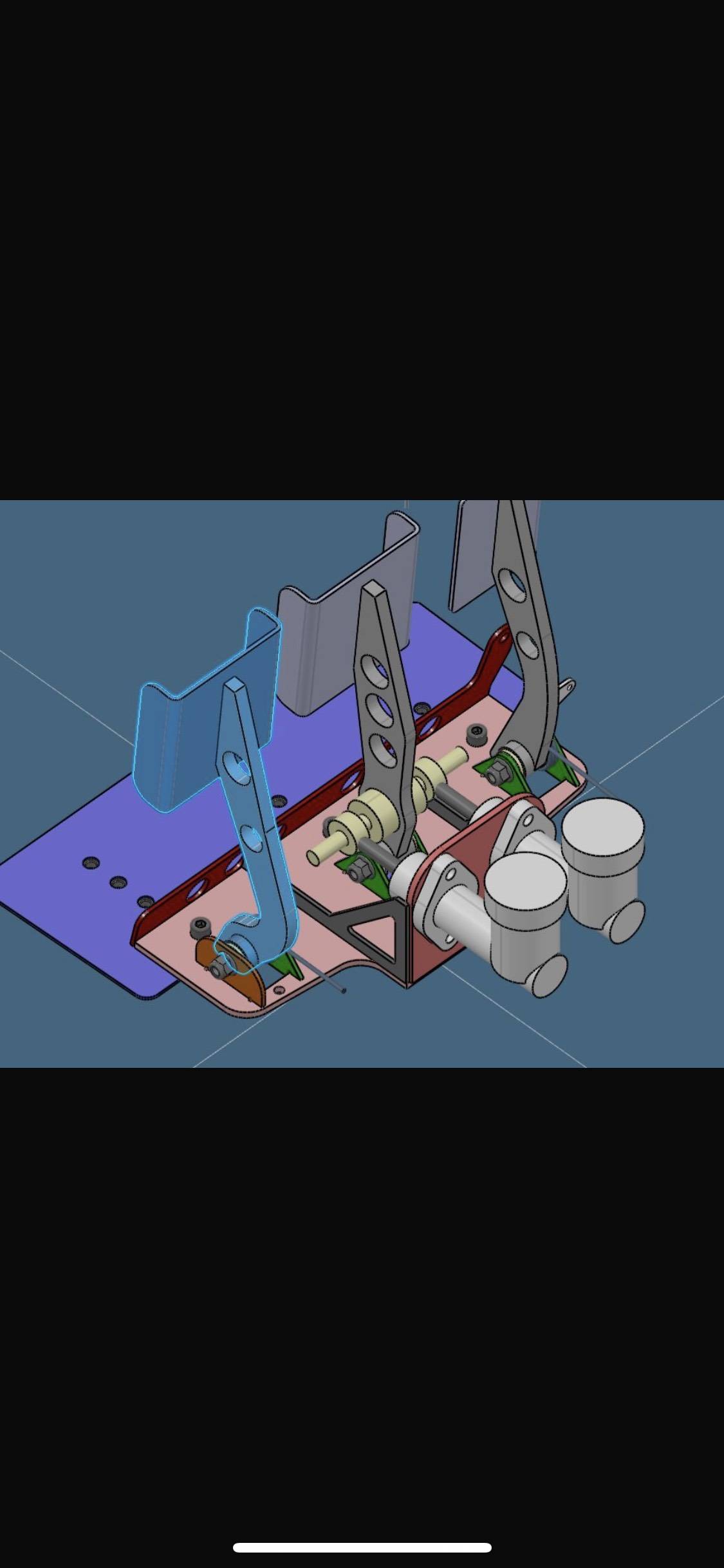

The goal is to create a detailed 3D computer-aided design (CAD) model of a pedalboard for a Formula Student vehicle. The design must respect the FSAE (Formula SAE) rules and technical regulations, ensuring it meets all safety, performance, and dimensional requirements set by the competition

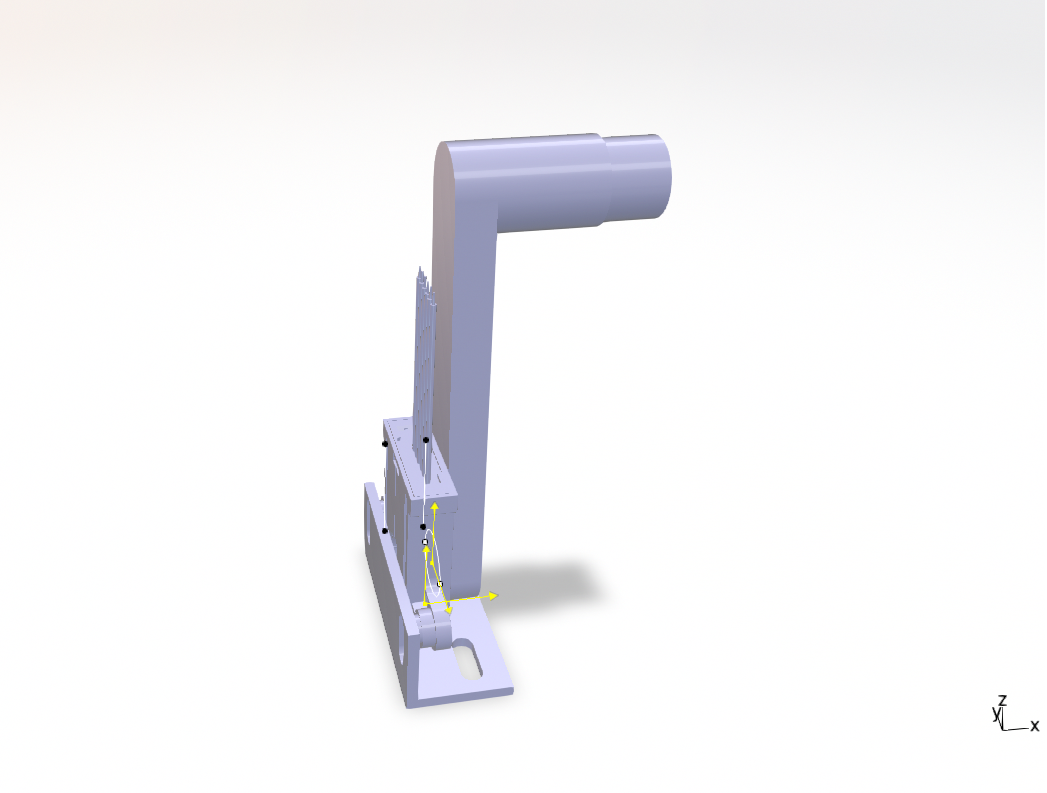

We had to sandblast all the parts of the crankset to apply an anti-rust paint that clings well.

In order to retrieve the pedal position, we had to devise a system using a hall-effect sensor to provide us with all the data we needed to comply with the pedal regulations, and at the same time link this information to our single-seater ECU.

Fusce ipsum diam, consequat nec rhoncus ut, bibendum sit amet lorem. Suspendisse nec neque nec quam dictum scelerisque et eu quam. Proin interdum vestibulum urna eleifend feugiat. Integer id ipsum pretium, egestas augue at, suscipit turpis.

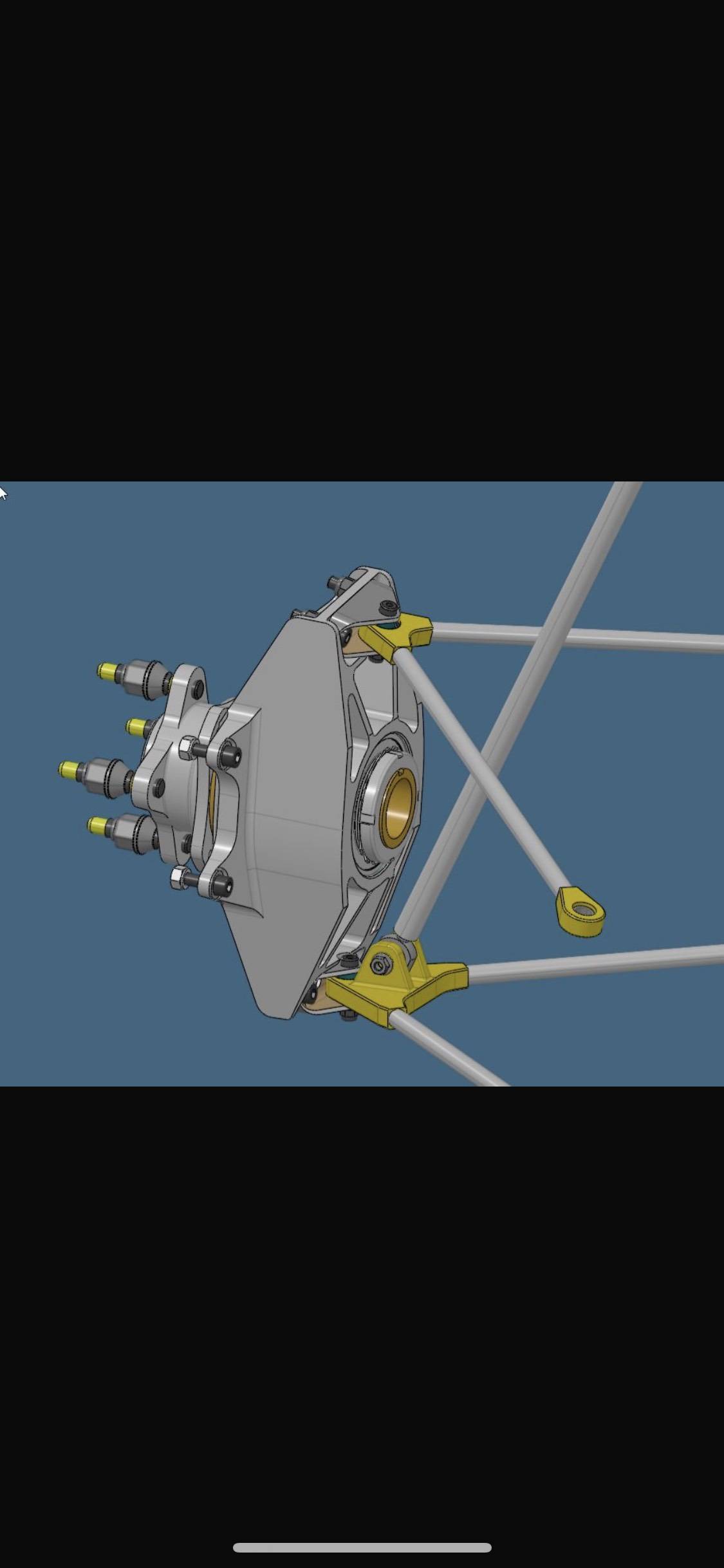

To position the motor correctly, we had to calculate the center of gravity. This was done by my classmates from the Arts et métiers team formula student.

A beam problem forced the elec team to check the continuity of all beam circuits.

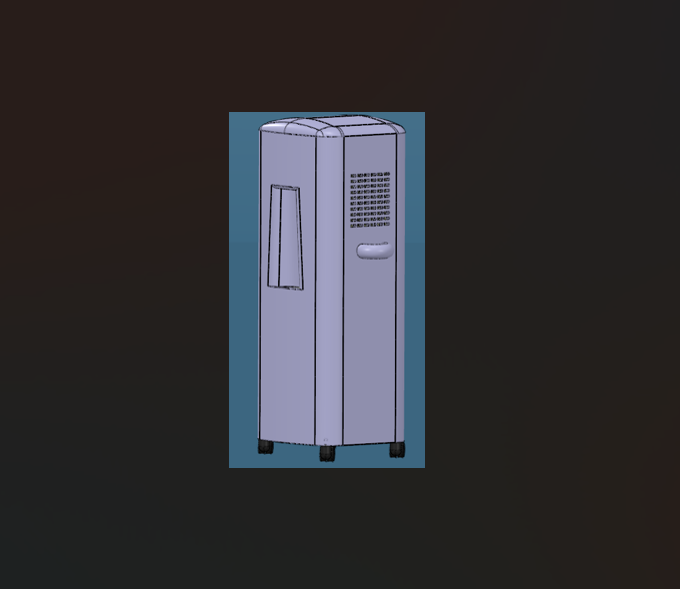

I did all the CAD to show a prototype of our machine on the day of the competition, if we were able to set up our own company. This machine includes a surface-mounted framework and surface-mounted and volume-mounted parts.

Here we can see the entire filtration system, from air to water. H14 filters are used to filter out airborne micro-particles. We also have a 3-stage water filtration system: GAC filter for the primary stage, RO membrane with UV filtration and ozonation for the secondary stage, and a remineralization system.

In this project, I was in charge of all CAD and specifications with Victor, who was project manager. Aymeric, an MBA student at MBway, was in charge of the commercial side (BMC, Business Plan, Pestel, SWOT). We hold regular brainstorming sessions to assess the viability of our models.